Introduction to the pf940v2 jig

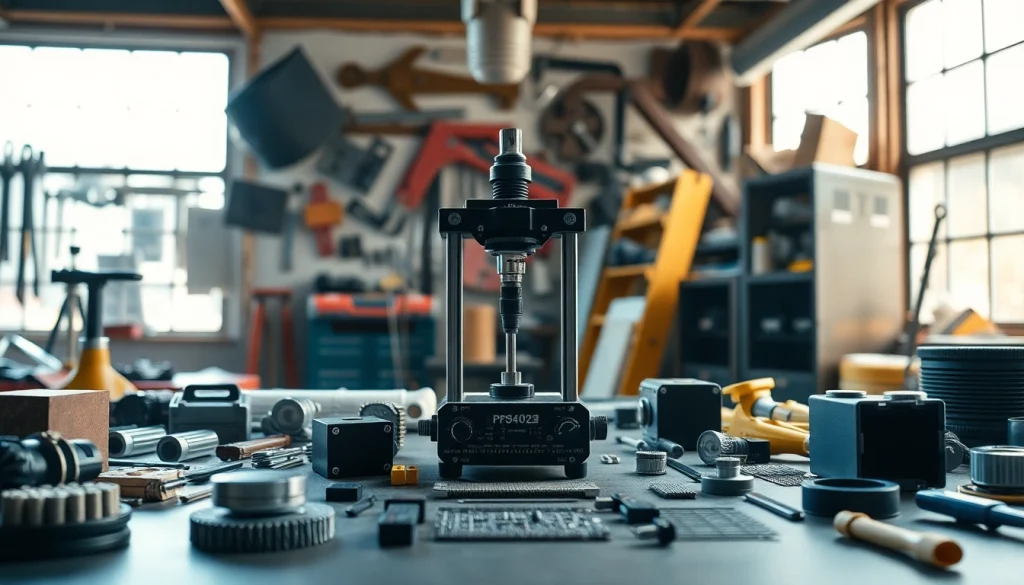

The world of firearm customization has experienced a surge in popularity thanks to innovative tools like the pf940v2 jig. This jig enables enthusiasts to create their own custom frames with precision and efficiency, enhancing the overall experience of building personalized firearms. In this article, we’ll delve into everything you need to know about the pf940v2 jig—from its features and benefits to setup, usage, and maintenance.

What is the pf940v2 jig?

The pf940v2 jig is a specialized tool designed for aiding in the assembly and modification of an 80% frame for handguns. Specifically, it provides DIY enthusiasts with the necessary components to accurately shape, drill, and finish the frame according to their specifications. The jig fits securely around polymer frames and guides the user through the machining process, ensuring consistent results and adherence to design parameters.

Essential Features

- Durable Construction: The pf940v2 jig is made from high-quality materials that withstand the machining process, providing stability and precision.

- Easy Setup: Designed for user-friendliness, this jig can be set up quickly, requiring minimal tools and effort.

- Multiple Configurations: The versatile design accommodates various tools for milling, drilling, and finishing, making it adaptable for different preferences.

- Comprehensive Instructions: Users receive clear guidance for setup and operation, empowering even beginners to use the jig effectively.

Benefits of Using the pf940v2 jig

Using the pf940v2 jig offers several advantages:

- Cost Efficiency: Building your firearm can be significantly cheaper than purchasing pre-assembled ones, especially with the current availability of affordable kits.

- Customization: This jig promotes personal expression, allowing users to customize their firearms to meet their specific needs and tastes.

- Satisfaction of DIY Projects: Successfully completing a project enhances skills and provides a sense of accomplishment that commercially produced firearms can’t match.

- Enhanced Skill Set: Engaging in the crafting process helps users gain valuable skills in machining and firearm knowledge.

Setting Up Your Workspace for the pf940v2 jig

A well-organized workspace is crucial for successful usage of the pf940v2 jig. Here are detailed tips on how to establish your workstation efficiently.

Perfect Layout Configuration

Begin by designating a clean, spacious area dedicated solely to your project. Ensure this area is well-lit to enhance visibility while machining. Consider utilizing a sturdy workbench that can withstand the pressure of tools and activities associated with operating the pf940v2 jig.

Recommended Tools and Equipment

For optimal performance with the pf940v2 jig, you should have the following tools on hand:

- Drill press or hand drill

- A set of end mills and drill bits

- Calipers for measurement

- Safety glasses

- Clamps to secure the jig in place

- Deburring tools

Safety Precautions

Safety should be your top priority when working on any DIY project, especially with power tools. Always wear appropriate safety gear such as goggles and gloves. Ensure that all tools are in good condition and that your workspace is clear of any hazards that could lead to accidents. Familiarizing yourself with the tools and practicing safe handling procedures is essential to prevent injuries.

Step-by-Step Instructions for the pf940v2 jig

Using the pf940v2 jig effectively requires a step-by-step approach. Here’s how to get started:

Preparing Your Frame Kit

Begin by unpacking your frame kit and ensuring that all necessary components are present. Lay out the components in an organized manner. Read the included instructional manual thoroughly to understand the specific instructions related to your frame type for the best results.

Using the pf940v2 jig Effectively

Follow these steps for effective use of the pf940v2 jig:

- Secure your frame within the jig, ensuring it is clamped firmly.

- Using a drill press or hand drill, carefully drill out the necessary holes according to the instructions. Take your time, adhering to recommended speeds and techniques.

- Use end mills to precisely shape the frame, following the guide provided by the jig. Be cautious to not exert excessive pressure, which could damage the frame.

- Regularly check your progress against specified measurements to ensure accuracy.

- Once completed, use deburring tools to smooth out any rough edges, ensuring a clean finish.

Troubleshooting Common Issues

While using the pf940v2 jig, you may encounter some challenges. Here are common issues and suggested solutions:

- Misalignment: If the frame appears misaligned, double-check the installation of the jig and ensure all clamps are tight.

- Excessive Friction: If you encounter too much resistance during machining, verify that you’re using the correct speed settings and appropriate lubrication.

- Inconsistent Cut Depth: Regularly measure your progress to ensure depth consistency. Make small adjustments as necessary.

Comparing the pf940v2 jig with Alternatives

In the vast landscape of jig options, it’s essential to evaluate how the pf940v2 jig stacks up against alternatives.

Key Differences and Advantages

Unlike many competitors, the pf940v2 jig boasts a user-centric design that enhances ease of use without compromising on accuracy. Its robust construction and comprehensive instructions distinguish it from other jigs that may lack such clarity.

User Feedback and Reviews

Testimonials from users highlight the pf940v2 jig’s effectiveness in simplifying the assembly process. Many commend its accuracy and durability, underscoring a community of satisfied builders who appreciate the level of customization it permits.

Price vs. Performance

While there are jigs available at both lower and higher price points, the pf940v2 jig offers a compelling balance of affordability and performance, making it a wise investment for serious enthusiasts. When considering the cost, it’s important to evaluate the long-term satisfaction and quality results it delivers.

Maintenance and Long-Term Care of the pf940v2 jig

To ensure durability and consistent performance from your pf940v2 jig long-term, proper care is essential.

Cleaning Techniques

Regular maintenance is crucial in preserving accuracy and functionality. After each use, clean the jig with a soft cloth, removing any debris or polymer shavings. Avoid using harsh chemicals, as they may damage the materials. Regular inspections for wear should be part of your cleaning regimen.

Storing Tips

Store the pf940v2 jig in a dry location, away from direct sunlight. Consider using cases or bags that can prevent dust accumulation while also protecting the jig from physical damage.

Longevity Strategies

To extend the life of your pf940v2 jig, avoid overusing the same drill bits, and schedule regular checks for alignment and wear. Maintaining a consistent cleaning routine will help you keep the jig functioning at peak performance.

FAQs About the pf940v2 jig

What materials can I use with the pf940v2 jig?

The pf940v2 jig is primarily designed for use with polymer frames but can accommodate specific aluminum and other compatible materials if specified.

How do I ensure accuracy while using the pf940v2 jig?

Measure twice and cut once! Regularly verify your work against specifications and engage in slow, precise movements during machining.

Can beginners use the pf940v2 jig safely?

Yes, beginners can use the pf940v2 jig safely by following instructions and using appropriate safety gear while becoming familiar with machining processes.

What are the most common mistakes with the pf940v2 jig?

The most common mistakes include misalignment, using incorrect settings for speed, and failing to double-check measurements during machining.

Is replacement documentation available for the pf940v2 jig?

Yes, replacement documentation can typically be obtained through the manufacturer’s website or customer service channels.